share

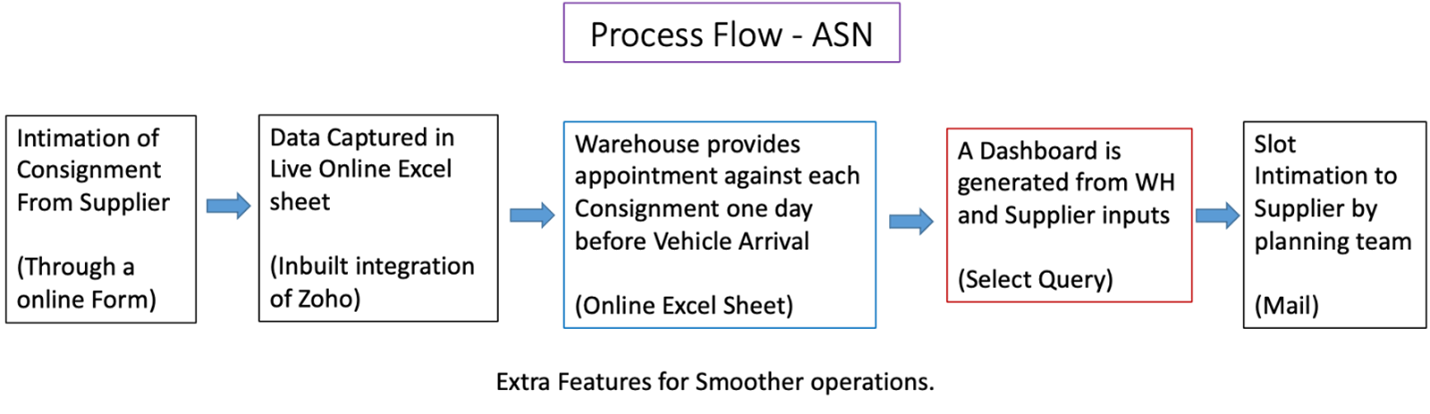

The development of the inbound logistics process and the related supply chain workforce centers around implementing a digital slot-based dashboard system. This strategic solution, which relies on the framework of the Advance Shipping Notification (ASN), is critical for realizing the delivery promise.

The overarching organizational goal is to establish a digital-first, AI-enabled, and human-augmented supply chain. The inbound process is standardized using components like the ASN Tracker and various digital forms, covering the flow from vehicle dispatch through to the Goods Receipt Note (GRN) status update.

Problem

Without timely intimation regarding the arrival of inbound trucks, the supply chain center faces several issues that restrict operational efficiency and service quality.

The core challenges that this automation solution addresses include:

Costly Delays: The supply chain center experiences unloading delays that can extend up to three days, resulting in high holding costs.

Service Risk: The lack of advance planning leads to stock-outs, posing a significant service risk.

Unpredictable Manpower Demand: Manpower utilization is not optimized because demand is unpredictable. This effectively locks the existing workforce in low-value manual tasks rather than allowing them to transition into data-driven roles critical for future operations.

Lack of Planning Visibility: Warehouse staff note that they only become aware of trucks when they physically show up at the gate. This reactive approach makes it impossible to plan unloading efficiently, especially when up to five trucks arrive simultaneously.

Documentation Issues: There is delayed access to necessary documentation, including invoices and quality certificates.

Informal Communication: Suppliers report that there is no structured system for them to inform the center about dispatch, requiring them to rely on informal messaging.

Work or Strategy

The proposed solution involves deploying a Slot-Based Unloading Dashboard system which mandates that suppliers provide detailed ASNs. This strategy transforms the previously reactive inbound process into a proactive, scheduled workflow utilizing AI for optimization. The entire process of flow requires collaboration among the Planning, Warehouse, and Security teams.

The Structured Process (Two-Day Flow):

Planning and ASN Fulfillment

- ASN Fill Up: Planners must follow up with suppliers to ensure the ASN form is filled by 2:00 PM, detailing the next day’s vehicle arrival. The form must include the product, quantity, and Estimated Time of Arrival (ETA).

- Plan Entry: Category planners must enter the next day's vehicle arrival plan into the ASN tracker.

- Capacity Check: The Inventory Representative must share the vacant capacity status of the deep and chiller storage areas based on the vehicle plan.

- Slot Allocation: Team leads will finalize the unloading slots for the next day, and the Unloading Executive will enter these slots into the ASN Tracker. This process incorporates AI slot allocation to create an optimized unloading schedule.

- Compliance Rule: A strict rule dictates that if a supplier is not filling the ASN form during dispatch, their vehicle is not to be unloaded. The new system installed in the Warehouse office is strictly to be used for ASN activity only.

Arrival and Slot-Based Unloading

- Pre-Arrival Documentation: Vendors must upload invoices and food certificates for pre-dispatch.

- Vehicle Reporting: A QR code is generated and pasted on the truck. As the vehicle reports to the facility, the Security Representative must enter the Reporting Date and Reporting Time for every vehicle in the ASN Tracker. The security guard scans the QR code, resulting in automatic entry into the CRM. If a vehicle that was absent in the plan arrives, it must be added to the ASN tracker.

- Slot Execution: Vehicles are unloaded according to the given slots. The unloading executive must note the Dock in and Dock out time 100% for every vehicle getting unloaded.

- Contingency Management: If an allotted vehicle is not available, the slot can be given first to a Courier Vehicle, and if not available, to an extra vehicle. If no planned, courier, or extra vehicle is available, the Unloading Executive can prepone the slot of the last slot-given vehicle which can be unloaded in the current slot. FIFO (First-In, First-Out) is not mandatory in this scenario.

- GRN Update: The GRN Executive must provide the GRN status to the Unloading Executive, who then enters the GRN Status of every vehicle, along with the reason if any GRN is on hold.

Benefits

The implementation of the ASN and digital dashboard system delivers tangible improvements in efficiency and supports strategic objectives.

Quantifiable Outcomes:

- Reduced Unloading Time: Unloading time is projected to be reduced from three days to less than one day (<1 day).

- Cost Savings: The center can achieve a 40% reduction in holding cost savings.

- Efficiency: There is a projected 15% better utilization resulting in increased manpower efficiency.

- Inventory Control: The reduction in stock-out shortages is estimated at 5%.

- Compliance: Documentation compliance will reach 100%, as necessary documents are available pre-arrival.

Strategic Outcomes:

- Accountability: Vendor accountability is enhanced through the reliance on structured data and compliance requirements.

- Workforce Uplift: The solution fosters a digitally literate workforce, moving employees from manual Excel/MIS work to managing dashboards and utilizing analytics.

Scope

The scope of this solution goes beyond technical implementation; it focuses on the Future of Work by transforming jobs and necessary skills across key stakeholders. The implemented solution is the foundation for an AI-driven supply chain capable of functions like ETA prediction and integration with robotics.

- The implemented solution is the foundation for an AI-driven supply chain capable of functions like ETA prediction and integration with robotics.

- Manage dashboards, create & update forms, manpower planning from reactive, manual Excel/MIS

- QR scanning and real-time slot confirmation instead of manual logs

- Digitalization of necessary documentation for the vendors/suppliers, using CRM and QR