share

From Restaurants to Raw Birds — And Why Profit Starts Long Before the Plate

By Smartlinks

When we think about the poultry business, most conversations revolve around restaurant menus, consumer demand, and retail shelves. But profitability in poultry doesn’t begin at the point of sale — it starts much further upstream, deep within the complexities of the poultry supply chain. In the last post, we explored the world of restaurants, menus, and receipts — where the final demand for chicken is recorded, plated, and paid for.

But to truly unlock profitability in the poultry value chain, we must go much further upstream — to where the chicken is raised, cut, and packed.

The End-to-End Poultry Supply Chain: A Complex Ecosystem

From hatcheries and farms to slaughterhouses, deboning plants, distribution centres, and finally to consumer markets, the poultry supply chain is a delicate orchestration of biological, operational, and commercial realities.

However, poultry businesses face a unique and unavoidable challenge: “You can’t grow chickens to a purchase order.”

Every processor grapple with:

- Low forecast accuracy due to volatile consumer demand.

- Disconnected supply and demand planning, especially with biological yields.

- Manual, non-consolidated planning processes that lead to firefighting.

- Inefficient cut optimization, resulting in surplus cuts piling up in cold storage.

- No profit-centric planning frameworks, making margin optimization an afterthought.

- Batch traceability and compliance issues.

- Multiple finished goods from a single raw material (whole chicken), complicating allocation.

On top of this, unplanned meat waste, inactive sourcing and production lines, and expiry management challenges eat into profitability.

The Real Planning Challenge: Biological Supply vs Precise Demand

Unlike other industries, poultry operates under a biological constraint. From a batch of 1200 birds, you can only get a fixed combination of cuts — breasts, wings, legs, giblets, and by-products. But customer demands don’t align so neatly:

- 500 kg of boneless breast for QSRs.

- 300 kg of drumsticks for events.

- 250 kg of wings for promotions.

This mismatch leads to:

- Excess inventory and frozen stock.

- Profit leakage from underutilized high-margin cuts.

- Reactive planning firefights every day.

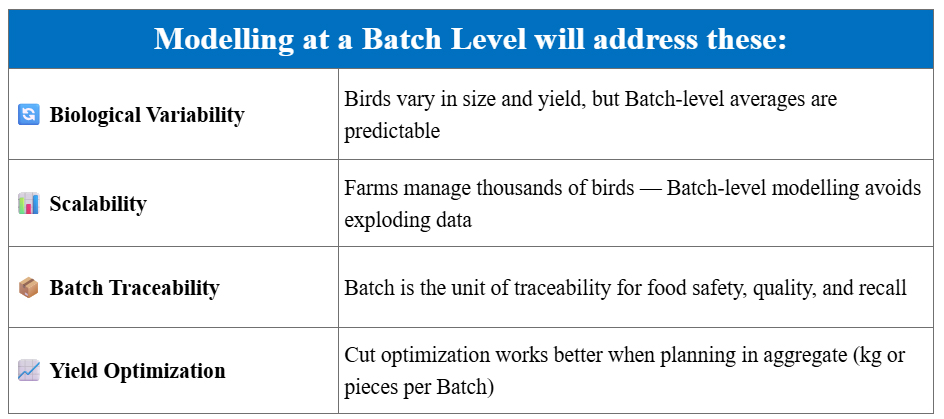

Modelling Poultry as a “Batch”, Not a Bird

The traditional approach of managing poultry supply chains on average yields or SKU-level planning is inherently flawed. At Smartlinks, we advocate a Batch-level planning model, which better reflects how poultry businesses actually operate.

Attributes like hatch date, breed, Feed Conversion Ratio (FCR), and projected slaughter date become essential inputs for batch planning. This approach allows planners to manage thousands of birds effectively while focusing on margin-driven cut allocation strategies.

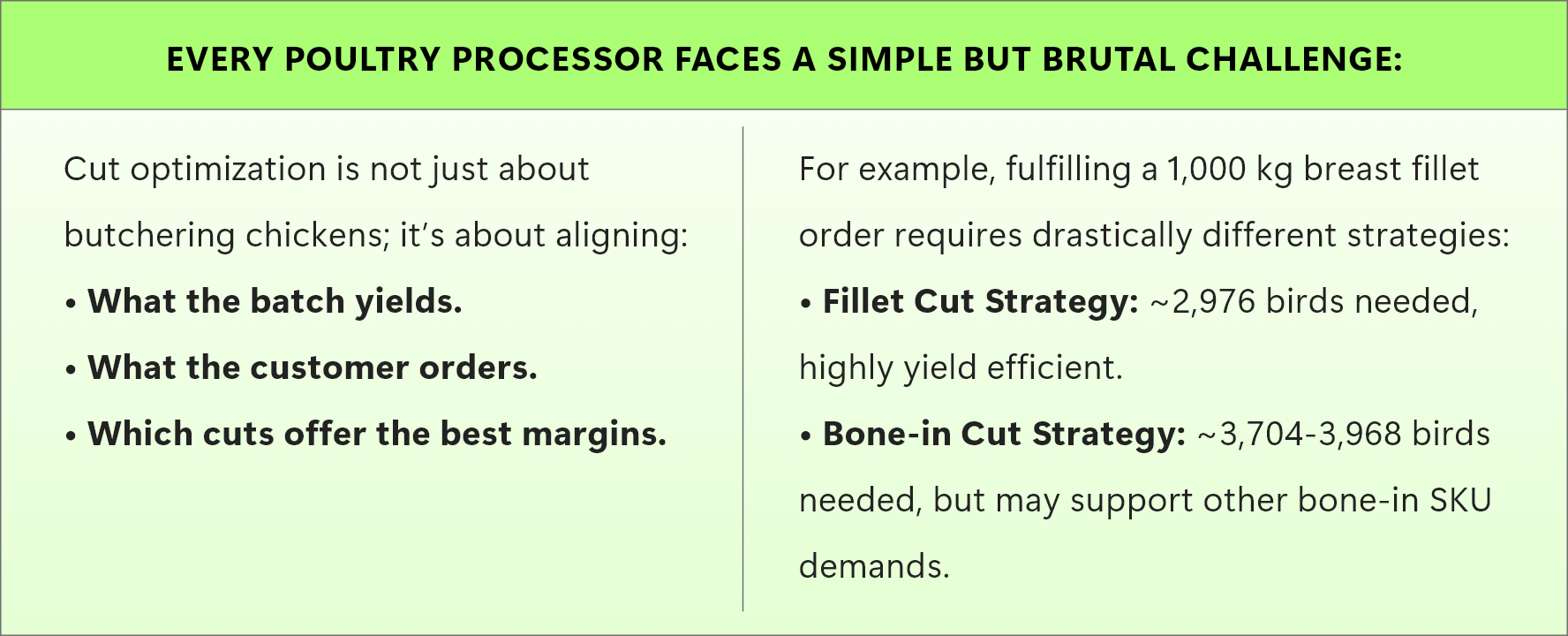

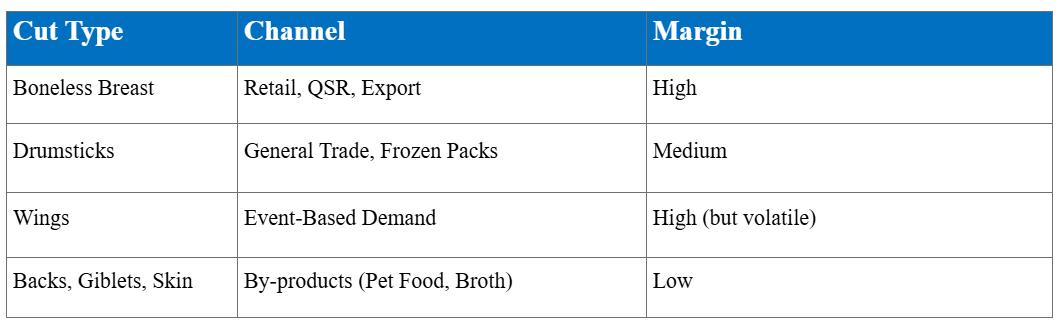

The Cut Optimization Puzzle — Where Profitability is Won or Lost

Thus, cut optimization isn’t just about meeting demand—it’s about maximizing profit while managing biological constraints. Without the right planning model, businesses risk over-processing, freezing excess inventory, and eroding margins.

Cut Allocation Complexity

A robust cut optimization model must dynamically allocate supply across channels, balancing demand fulfilment with profit maximization.

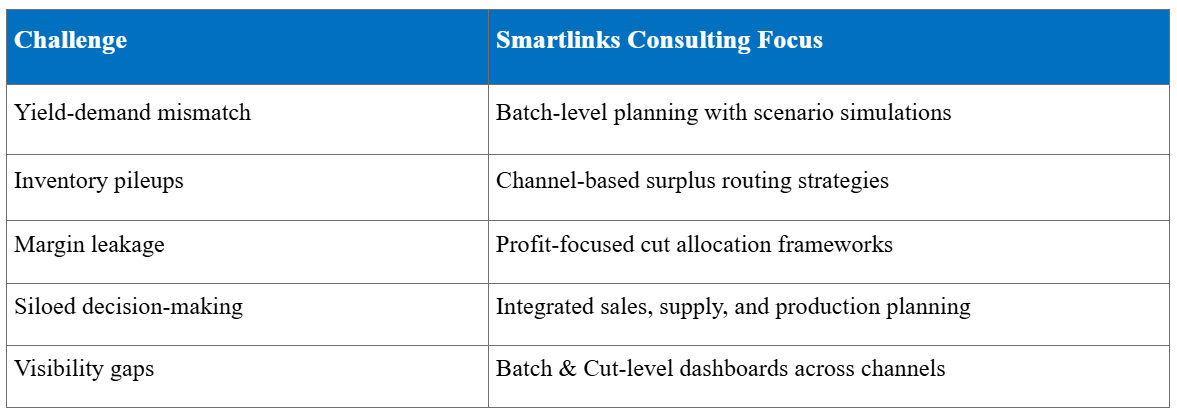

How Smartlinks Helps Poultry Businesses Transform Planning

At Smartlinks, we believe planning is the profit Center of poultry operations. Our approach is not tool-centric; it’s architecture- and decision-centric, helping businesses build a planning ecosystem that is biologically accurate and commercially sharp.

Potential Benefits of Batch-Based Cut Optimization

- Higher Profitability: Prioritize high-margin cuts per batch.

- Lower Waste: Minimize frozen stock through proactive surplus planning.

- Better Fulfilment: Meet SKU-level demands reliably.

- Scalable Execution: Align production, sales, and sourcing teams on a single batch model.

- Compliance Readiness: Ensure traceability and quality standards.

From Farm to Fork — Plan Smarter, Cut Wiser

The poultry business is not just about managing inventory; it's about mastering biological variation, perishable timelines, and a diverse channel mix — all at once.

At Smartlinks, we help poultry businesses transition from reactive planning to proactive profit optimization. Our consulting frameworks ensure you are not just processing birds, but orchestrating profits.

If you’re still planning with averages and hoping the cuts align — it’s time to cut smarter, plan better, and think margin-first.