share

In poultry processing, production efficiency starts much before cutting begins. One of the most critical challenges is ensuring that different poultry types arrive at the slaughter plant in the correct sequence and at the right time, without disrupting production.

This post outlines a scenario-based modelling approach to manage inbound transport planning for poultry, considering production sequence, arrival buffers, and unloading constraints..

Business Scenario

- Poultry types must be loaded and processed in a defined sequence.

- Each poultry type must arrive at the plant at least 1 hour before the cutting start time.

- Any delay may cause production halts or line imbalance.

- The processing sequence of poultry types is determined based on lab test results and applicable conditions (e.g., disease rate thresholds such as 1% or 2%).

Arrival Constraints Example

Key Rule: Plant arrival time = Cutting start time – 1 hour

Modelling Approach

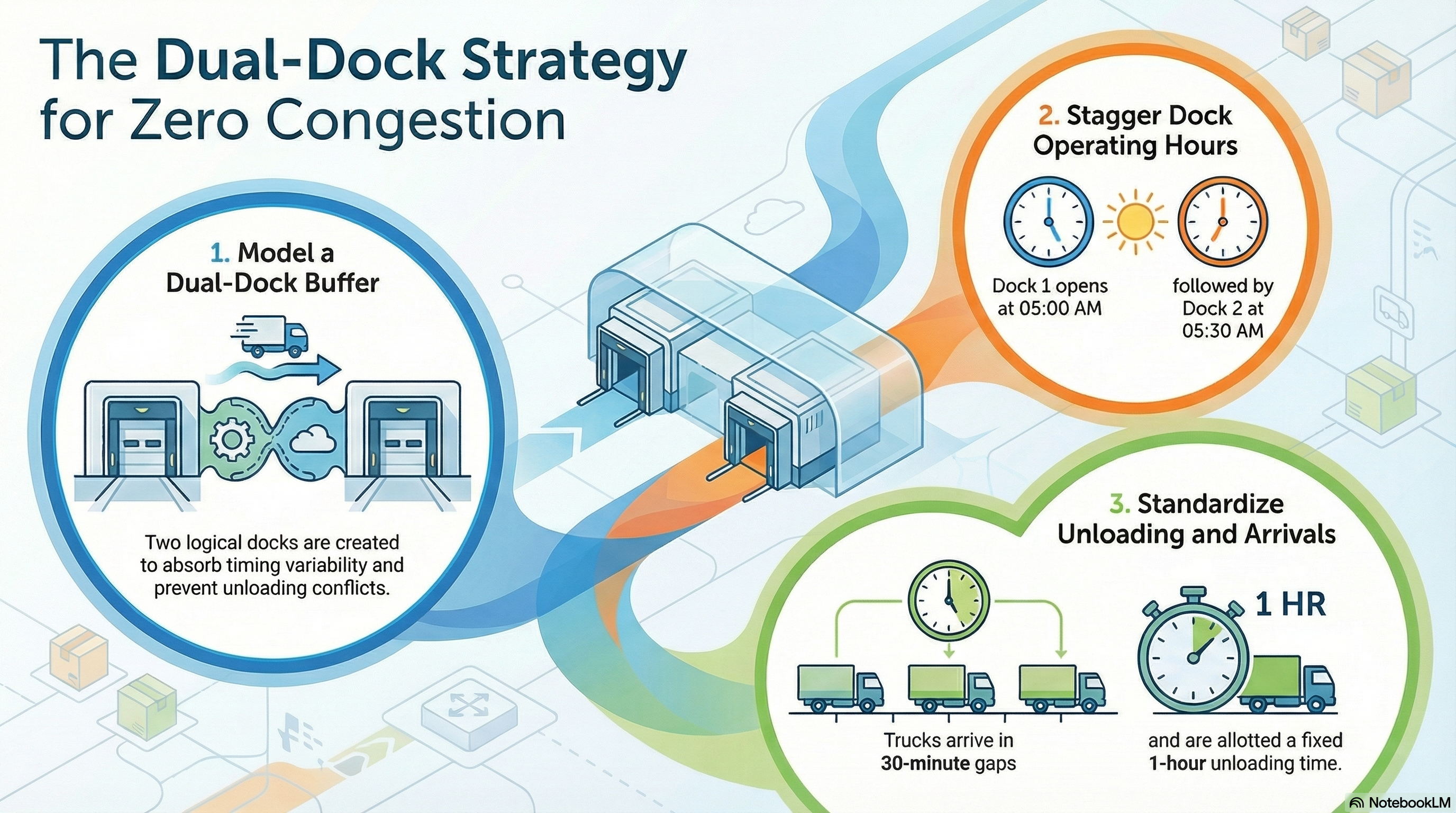

To ensure on-time arrival without congestion, the following approach is used:

1️ Dual Dock Modelling (Logical Docks)

- Two docks are modelled to create buffer capacity

- These docks are logical constructs, not equal to physical docks

- Purpose: absorb timing variability and prevent unloading conflicts

2️ Dock Operating Hours

- Plant business hours: Open 24 hours

- Dock 1: Opens at 05:00 AM

- Dock 2: Opens at 05:30 AM Based on minimum 30-minute cutting duration

3️ Unloading Time

- Fixed unloading time: 1 hour per truck

- Truck arrivals are staggered in 30-minute gaps

- This ensures sufficient unloading bandwidth without overlap..

Dock Arrival Pattern Visualization

✔ This staggered pattern avoids congestion ✔ Supports continuous cutting without stoppages.

Transport Planning Constraints Considered

The inbound optimizer evaluates multiple constraints together:

- Planning horizon & frequency

- Consolidation across locations (fixed routing)

- Equipment type & volumetrics

- Mixing of commodities

- Location-level restrictions

- Production line sequence

- Loading & unloading times

- Driving rules

- Carrier allocation based on cost

Simulation & Validation

- During solution construction, simulations are run

- Load behaviour is analysed against: Arrival gaps Dock utilization Production continuity

- Adjustments are made if deviations are observed

Key Takeaway

By modelling time buffers through logical docks, rather than relying only on physical capacity, this approach:

- Ensures sequence adherence

- Prevents production halts

- Balances operational feasibility and cost optimization