share

In every supply chain organization, one big question eventually lands on the table: Where should we run our Material Requirements Planning (MRP) — in ERP or in our Advanced Planning System (APS)?

It’s not a decision for one person in IT or operations. It’s a cross-functional planning team decision that affects multiple planning functions along with finance, and IT.

Why the Whole Team Should Care?

MRP is the process that turns demand signals into actionable supply plans. It impacts:

- Production readiness: Do we have the right materials on time?

- Supplier commitments: Are orders released accurately and early enough?

- Inventory health: Are we overstocking or risking shortages?

If the planning team chooses the wrong platform for MRP:

- Decisions may lag due to slow or inconsistent data updates

- Duplicate work may occur in maintaining master data in two places

- Different teams may rely on conflicting “versions of the truth"

The Role of Constraint Planning

Constraint planning adds another layer to this choice. When you must account for limited production capacity, supplier constraints, or material shortages, the platform you choose determines how realistic your MRP outputs are.

ERP MRP: Fast, tightly linked to execution, but traditionally unconstrained — it assumes capacity and supply will be available unless you add advanced modules.

APS MRP: Natively constraint-aware — factors in machine capacity, labour, supplier limits, and alternate sourcing in one run.

Hybrid: APS creates a realistic, constraint-based plan; ERP executes it with speed and stability.

If constraints regularly disrupt your plans, APS or a hybrid model becomes far more valuable for the planning team.

Option 1: MRP in APS

Best for: Teams needing high agility, scenario planning, and constraint-based accuracy.

Advantages for the team:

- Collaborative simulations: Multiple planners can run and compare “what-if” scenarios before committing.

- Constraint-aware planning: Considers capacity, alternate BOMs, and engineering changes.

- Short-term adaptability: Ideal for rapid response to demand/supply changes.

- Cost Accounting Support: Even when MRP is run in APS, its output can be written back to ERP for execution, ensuring finance teams still have what they need:

- Direct Material Costing: APS MRP outputs provide quantities and timing for cost computation.

- Raw Material Inventory Valuation: Supports FIFO, LIFO, or other valuation methods.

- Variance Analysis: Enables planned vs. actual consumption comparisons.

- Purchase Price Variance: Compares planned purchase prices with actual prices paid.

Team challenges:

- Requires tight integration with ERP for real-time master and transaction data.

- Additional cost reporting logic may need to be set up within APS.

- Execution still depends on ERP — both systems must stay synchronized.

Option 2: MRP in ERP

Best for: Teams prioritizing stability, integration, and fast execution.

Advantages for the team:

- One system of record: All planners reference the same master data, BOMs, and orders.

- Zero integration delay: Planned orders are instantly ready for execution.

- Direct link to costing: Inventory valuation, variances, and purchase price analysis are built-in.

Team challenges:

- Less flexible for rapid “what-if” planning.

- Harder to model multiple scenarios across different planning horizons.

- Constraint planning requires additional modules or external tools.

The Hybrid Approach

Many planning teams blend the two:

- APS for constraint-based planning & simulation: Model different demand/supply strategies with all constraints in play.

- ERP for execution: Push approved plans into ERP so it remains the operational source of truth.

This keeps agility high without sacrificing execution stability.

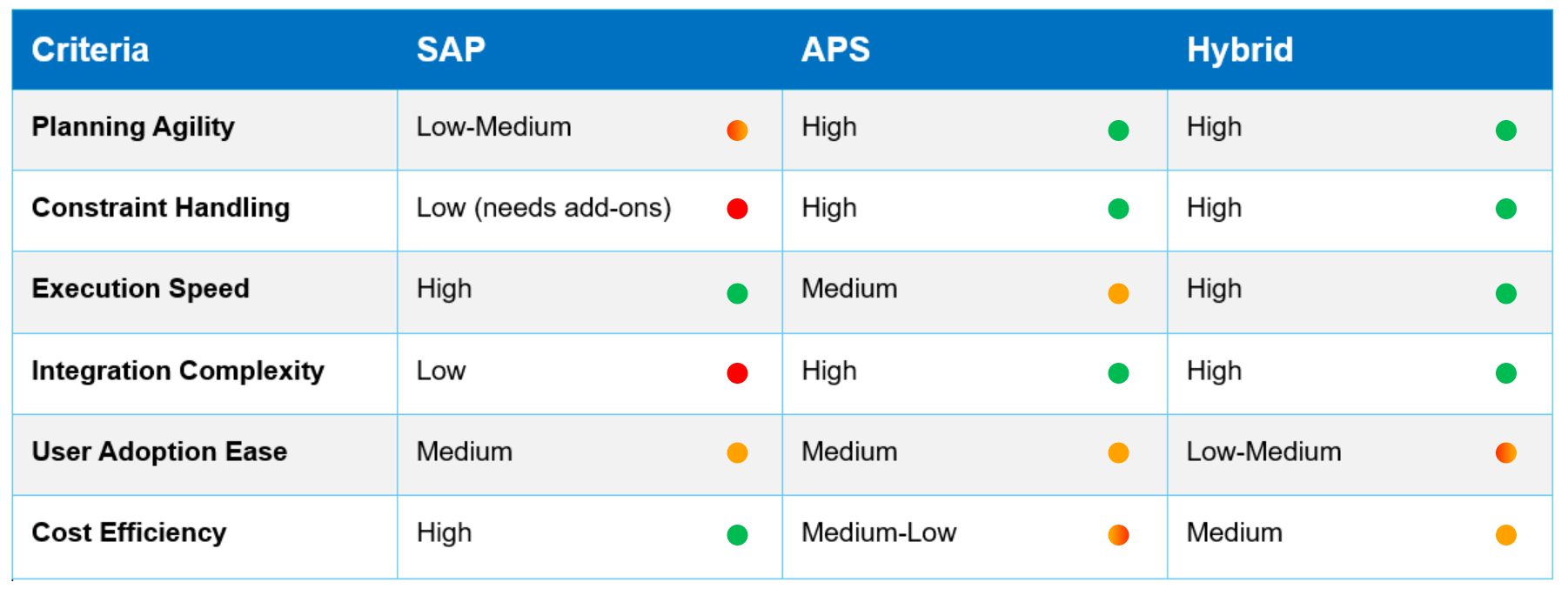

How the Planning Team Decides

Key discussion points for the team:

- Planning Horizon: Is agility in daily/weekly planning critical, or is long-term stability the focus?

- Frequency of Change: How often do we need to re-run MRP mid-cycle?

- Segmented Approach: Do you want to focus on all classes of products in the premium computing APS platform as per ABC classification?

- Integration Readiness: Can we maintain real-time, accurate data sync?

- Constraint Impact: Do capacity and supplier limits often cause re-plans?

- User Adoption: Which platform will the full planning team embrace and use effectively?

- Value for Cost: Are we leveraging APS capabilities enough to justify the investment?

Bottom Line

Choosing where to run MRP is a team sport. The best outcome comes when planning teams work together to design a process that fits the business rhythm and reflects real-world constraints.

- If execution certainty matter most: ERP may be the right home for MRP.

- If planning agility, realistic constraints matter most: APS could be the better choice.

- If you want both: go hybrid.

💡 Our view: The strongest planning teams don’t just pick a system — they design the end-to-end planning process together, ensuring technology enables, not limits, the business and making the best value of their IT investments.