share

In the world of high-value, temperature-sensitive shipments whether pharmaceuticals, dairy, or chocolates, the true challenge lies not just in maintaining compliance on paper, but in actively preventing and bridging gaps that can undermine product integrity. Trukr, powered by Smartlinks Platform, goes beyond conventional monitoring by embedding practical, data-driven strategies throughout the cold chain journey.

Cold Chain Gap Identification: Where Do Risks Lurk?

Even with robust compliance protocols, most temperature excursions and product losses occur at specific, predictable points in the chain—often before goods even reach crucial temperature-controlled zones. Through a holistic gap analysis, our experts map out every stage:

Supplier Pickup: Initial handling can be rushed or overlooked. Trukr digitizes this handoff and records the starting temperature, alerting operators to pre-load action if temperature threshold is exceeded.

Dock and Pre-loading Areas: Non-temperature-controlled conditions at loading bays, staging areas, and detentions can become silent culprits for cargo warming. Sensors deployed by Trukr here measure both ambient and product temperature, flagging risks before loading ever begins.

Loading Process: The movement from dock to truck is a critical window. Trukr guides staff to pre-cool containers and minimize ambient exposure by automating process alerts and prompting fast transfers when thresholds near limits.

In-transit Movement: Gaps emerge during unforeseen stoppages or route diversions. Trukr’s live alerting system notes every halt, activates predictive alerts, and triggers contingency protocols if temperature profiles deviate.

Unloading and Final Storage: Rapid unloading is crucial, but often not practiced. Trukr’s dashboards ensure unloading teams are ready, while post-unloading sensors record the temperature before warehouse intake, preventing hidden temperature spikes.

Proactive Gap Mitigation: Turning Insights into Real Actions

Where traditional systems merely record deviations, Trukr transforms data into actionable recommendations:

· Pre-cooling Protocols: Before loading, Trukr mandates pre-cooling of vehicles and containers, reducing the initial temperature differential that can shock sensitive products. Staff receive automated messages to begin pre-cooling at set times, so by the time goods reach the dock, the truck and storage units are already optimized for safe transfer.

· Live Temperature Guidance: Sensors installed on cargo directly transmit product temperatures, not just ambient readings. If temperature trends indicate a drift—even one degree away from optimal—Trukr dispatches correction advisories to both the truck and warehouse teams.

· Rapid Exception Response: When a potential breach is detected, exception management systems assess whether to reduce temperature further, speed up loading/unloading, or reroute the shipment. This allows immediate correction before goods ever exit compliance.

· Human Error Correctives: Training and staff reminders are part of every shipment journey. Trukr’s app periodically reminds operators of loading and stacking best practices, so goods are never improperly stored or exposed, even for a few minutes.

· Regulatory Adherence: On compliance fronts, Trukr’s detailed MIS reporting and automated logs meet regulatory demands for continuous traceability, giving brands peace of mind during audits and client checks.

Bringing Visibility to Operational Blind Spots

A key value-add is Trukr’s ability to illuminate and immediately respond to blind spots such as:

· Longer waiting times at staging points, where dock scheduling can cause temperature creep

· Unplanned truck stoppages during transit, triggering unscheduled re-icing or cooling interventions

· End-of-route delays where products may linger outside controlled areas before warehouse induction

Actionable insights here can include dock prioritization, process re-routing, or real-time adjustment of refrigeration setpoints to squeeze risk out of these moments.

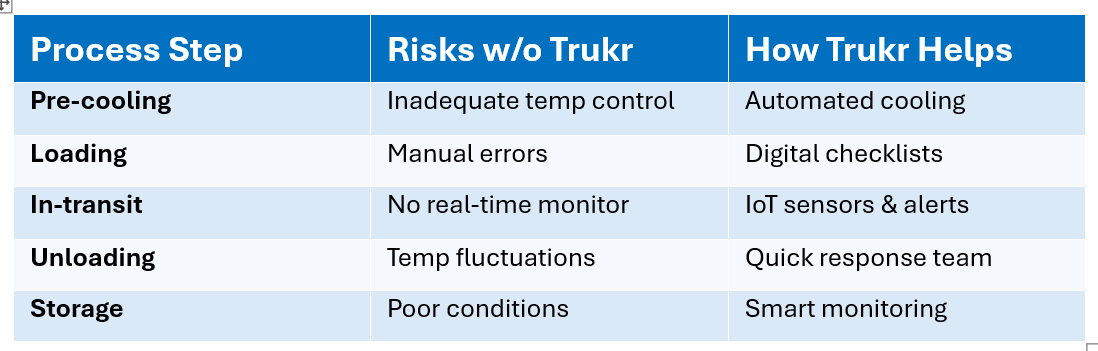

Trukr In Action: A Comparative View

Below is a diagram showcasing the contrast between a conventional cold chain and one enhanced by Trukr interventions.

Cold Chain Process Comparison: With vs Without Trukr

Putting It All Together: Empowered Teams and Unbreakable Chains

Cold chain compliance today requires more than just documented SOPs—it calls for smart partnerships between platforms like Smartlinks, hands-on gap analysis, automated process guidance, and rapid, corrective interventions at each vulnerable stage. The Trukr team isn’t just tracking; they’re actively orchestrating temperature control from pickup to final delivery, empowering operations to stay ahead of risks and secure lasting product quality.

By connecting live data, pre-emptive action, and actionable feedback, Trukr and Smartlinks help clients bridge that critical last mile between mere compliance and assured integrity, setting new standards for reliability in cold chain logistics.

With practical examples, actionable interventions, and high-impact visualizations, this expanded blog now provides a compelling, nuanced narrative that reads naturally and persuasively for industry audiences.

Information is Everything

Information is everything in today’s complex cold chain operations. For Trukr, every data point captured—from moment-to-moment temperature reads to the timing of a truck’s stoppage—feeds a deeper purpose than simply reporting compliance. These insights become the engine for executive decision making, allowing patterns in temperature breaches to be spotted across different regions or product lines, and enabling predictive models that estimate the impact of even brief excursions on shelf life and product quality. By translating granular sensor readings into actionable dashboards, Trukr empowers supply chain leaders to make informed interventions: rerouting shipments, refining pre-cooling routines, or updating risk protocols when recurring trends are identified. Over time, this intelligence not only catches problems but drives proactive, cost optimizing decisions that keep product integrity and business margins intact.